Ep Epoxy VPI SystemVacuum Pressure Impregnation Equipment Machine

for Transformer Cores

1. General Introduction

1.1 High vacuum pressurizing impregnating equipment is the key

equipment

for insulation treatment of high voltage motors, special

anti-explosion motors,

and transformers. The electric motor vacuum pressure impregnation (vpi) enhances the mechanical

strength, insulation, anti-moisture and anti-mold performance of

the windings.

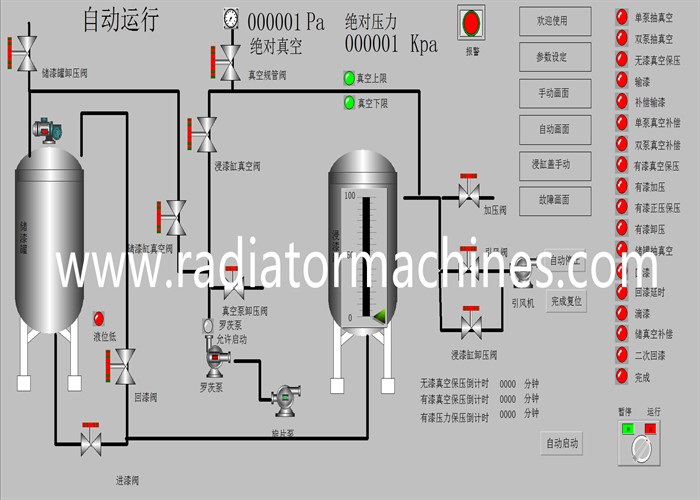

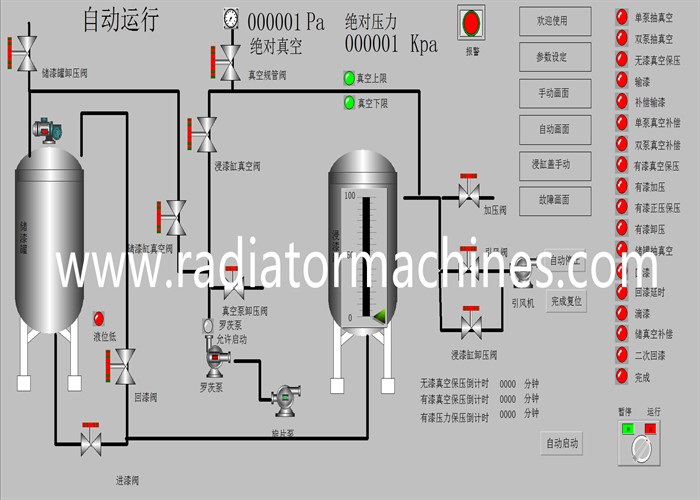

1.2 Installation, test-running and training are provided on the

buyer’s site. The

foundation drawing is also provided.

1.3 Installation type: vertical.

1.4 Technical documents to be provided: qualification certificate,

technical

features paper, main pressurized components material list, welding

line

radiographic examination report, spare parts nondestructive

examination report,

pressure vessel appearance and physical dimension test report,

welding test

plate mechanics and curving performance examination report,

pressure test

inspection report, inspection certificate of pressure vessel

product safety performance.

1.4.1 Manufacture standards: Steel Pressure Vessels GB150-1998;

Welding

Specification for Steel Pressure Vessels JB/T4709-2000; Vacuum

System

Design Standard JB/T7674-95.

1.4.2 sealing ring of the impregnating tank: air-filling type

sealing ring.

1.4.3 other documents: bought-in components documents and

electrical

components list; manual, foundation drawings, electrical diagram,

process flow charts, etc.

2.Supply Scope

| No. | Item | Q’ty |

| 1 | Vacuum impregnation tank | 1 set (vertical type) |

| 2 | Resin storage tank | 1 set (vertical type) |

| 3 | Vacuum system | 1 set |

| 4 | Resin supply and return system | 1 set |

| 5 | Hydraulic system | 1 set |

| 6 | Chilling system | 1 set |

| 7 | Heating system | 1 set |

| 8 | Control and measurement system | 1 set |

| 9 | Installation material | 1 set |

Technical Parameters

1. motor coil vacuum impregnation equipment System

1.1pressurizing and impregnating

cylinder, specification: Φ3000×3500mm, 1 piece;

1.2 working pressure: 0-0.6MPA (adjustable);

1.3 working vacuum degree: 200Pa;

1.4 material: head: 16MnR; body: Q345-R; flange: Q-235-B forging

parts;

1.5 The impregnating tank cover is opened and closed with the help

of a

hydraulic mechanism. The opening, closing, locking, and unlocking

are all

driven by the hydraulic cylinder. The movement signal is returned

by

non-contact proximity switch. The tank opening angel is well

designed so

that the projection of the top point of cover casts over the tank

inner wall.

In this way, when the tank cover is opened, the jobs could be

loaded into

the tank easily.

1.6 The vacuum pressure impregnation equipment is equipped with

overpressure alarm, and pressure safety device.

1.7 The vacuum varnish impregnation machine is designed with one

peephole light and one observation windows.

1.8 The vacuum pressure impregnation for electric motorsk is sealed

by a silicon rubber ring.

1.9 The flange used for the impregnating tank is made of Q235-B

forging parts.

1.10 When the impregnating tank cover is opened, the tank has

safety interlock mechanism.

1.11 The vacuum pressure impregnation plant inside is built with

weight bearing stand which can bear a maximum weight of 30T.

1.12 The epoxy resin vacuum impregnation equipment is equipped

with the level transmitter.

2. Resin Storage System

2.1 insulation paint storage tank, specification: Φ3000×3500mm, 1

piece;

installation type: vertical;

2.2 material for head: Q235-B; material for tank body: Q235-B;

flange:

Q235-B forging parts;

2.3 working vacuum: 8000-10000Pa;

2.4 The resin storage tank is designed with one peephole light and

two

observation windows.

2.5 This system is equipped with a mixer with speed at 25-36r/min.

The

motor and reducing gear drives the paddle agitator. The mixer and

its

positioning devcie are easily installed.

2.6 The resin storage tank has heating and chilling function.

2.7 The tank body is designed with a 100mm coil which is filled

with

heating/chilling glycol solution (condensation: 40%). The tank body

is

wrapped with heat preservation fiber and stainless steel plate as

cover plate.

2.8 The storage tank is equipped with the vacuum meter, the safety

device, the magnetic overturn level indicator, and low resin level

alarm.

The resin level is displayed on the touch screen. When the storage

tank

is short of resin, the resin supply valve will be closed

automatically to

prevent reverse shooting. The tank body is designed with the

temperature

sensor to measure the resin temperature.

3. Vacuum System

3.1 This epoxy vacuum impregnation machine pumping

system includes 1 set of H-150 slide valve pump,

1 set of ZJ600 roots pump and 1 set

of ZJ1200 roots pump.

3.2 max air suction speed: 1200L/S;

3.3 vacuum impregnation system to prevent vapor from

coming into the vacuum unit.

3.4 The waste gas of the vacuum system first

goes through a mechanical trap condenser before

entering the atmosphere. The condensed liquid will be let out

manually.

3.5 The vacuum valves used are of high vacuum pneumatic ones.

3.6 intelligent digital magnetic resistance vacuum meter, and

absolute

pressure transmitter.

3.7 electrical contact vacuum meter, electrical contact pressure

gauge.

3.8 circulation water tank, pump, valves and pipeline.

4. Hydraulic system

4.1 The hydraulic system is comprised of the hydraulic pump, oil

tank, oil

pipes, motor and electro-magnetic valves.

4.2 design pressure: 16MPA, working pressure: ≤12MPa .

4.3 The hydraulic oil should be provided by the buyer.

4.4 The hydraulic mechanism is used to open, close, lock and unlock

the

impregnating tank cover.

4.5 The hydraulic cylinder is set with anti-fall function, and its

working

peed is adjustable.

5. Resin Supply and Returning System

5.1 Resin supply and returning process is conducted through the

differential

pressure caused by the vacuum environment of the resin storage

tank.

5.2 All the valves are high vacuum automatic pneumatic ball valves.

5.3 This system also includes seamless pipes, punched elbows,

flanges,

and other standard parts.

5.4 The system adopts the fine and rough filtration 2-grade filter.

6. Pneumatic System

6.1 It is comprised of pneumatic triplet joints, pneumatic

fittings, and solenoid valves.

6.2 Working pressure: 0.4-0.7Mpa.

6.3The air source for the valves and the impregnation tank are to

be provided

by the customer.

6.4 The air source is provided by the customer.

7. Heating system

7.1 It is comprised of the electrical heater, the temperature

sensor, valves,

and the pressure gauge.

7.2 Heater power: 36kw. The heater heats the circulation water

circulating

in the jacket layer.

7.3 This system is used to keep the resin liquid within a certain

temperature

range.

7.4 The temperature is equipped with the automatic controller.

There is

also one overtemperature alarm. When the actual temperature exceeds

the limit

valve, the heater stops heating.

8.Chilling System

8.1 cilling machine, 1 set; power: 30Hp, 380v; refrigerating

capacity:

60000W/H; cold water flow rate: 15M3/h;

8.2 This system is comprised of the cold water tank, the pipe pump,

the pressure gauge, the expansion tank, the valves, and the pipes.

8.3 This system is used to cool the varnish storage tank and the

condenser.

8.4 This system is used to cool the varnish. The heating system is

in parallel connection with the chilling system.

8.5 The ON/OFF and fault of the chilling system is shown on the

touch screen. And there is an automatic alarm on the touch

screen when fault occurs.

9.Pressurizing system

9.1 Absorption dryer, 1 set (treatment gas volume: 3.6 m³/ Min,

exhaust pressure: 7 kg / cm2, power 22kw, 380V / 50Hz);

9.2 0.6m ³ air storage tank;

9.3 HMC precision filter, 1 set;

9.4 Air water separator, control valve, pressure gauge, pipeline,

etc.

9.5 Controllable and adjustable when pressurized to 0.6MPa;

10.control system

10.1 control cabinet, 1 piece ( plastic-spraying coating);

voltage: 380V, 3 phase, 50HZ;

220V, 1 phase;

10.2 PLC control and industrial computer control system

( both auto and manual available);

PLC brand: Mitsubishi PLC;

10.3 industrial computer with 21 inch liquid

display (search and printing of vacuum degree, pressure, and resin

level);

10.4 mouse operation. The touch screen is operation

friendly, and has both the operator access and manager access.

10.5 the touch screen could be connected with the printer

(printer should be prepared by customer). The touch screen

has preserved this printer interface.

10.6 remote control level indicator. The resin level is

monitored digitally all the time by the control system.

10.7 Real-time recording and printing of product number

and technical parameters, parameter curves, process

physical parameters: vacuum degree - time, pressure - time,

and resin level - time.

10.8 It can automatically collect and record vacuum and

pressure, and has memory function.

10.9 Display the vacuum degree, pressure and other parameters

measured, indicating the whole processing process. Store them

in the form of time-pressure and parameter curve on the

computer hard disk. Keep records for a long time. They can be

inquired and printed at any time, and output user information in

the form of table (impregnation process parameters, time,

operator number, part number, etc.).

10.10 The power supply of the equipment adopts AC380V and

50HZ three-phase four-wire system. All the main equipment and

wires adopt high-quality brand products to ensure safety and

reliability.

10.11 The process of resin supplying and returning is automatic.

When the fault occurs, it can be switched to manual operation.

When vacuum degree or pressure exists in the tank, the hydraulic

system doesn’t work when the operator closes the tank cover.

10.12 It has necessary mechanical and electrical interlocking and

alarm functions. Prevent overpressure and artificial wrong

operation.

11. Installation material

11.1 seamless steel pipe, 1 set;

11.2 standard flanges, and elbows;

11.3 various bolts;

12. Product Warranty

The VPI-3000 impregnating equipment is warranted for 13 months

starting from the date of shipment, but the seller is not

responsible

for damages or faults caused by misoperation, force majeur

situations or

damaging behaviors on purpose by the workers.

13. Installation and Test Running

The seller is to provide on-site installation and test-running

assistance to

the seller. The seller is also to provide the foundation drawing

for the buyer.

Tools and facilities prepared by the buyer: electrical welding machine,

cutting machine, polishing machine, oxygen, acetylene, electricity,

water.